- Empty cart.

- Continue Shopping

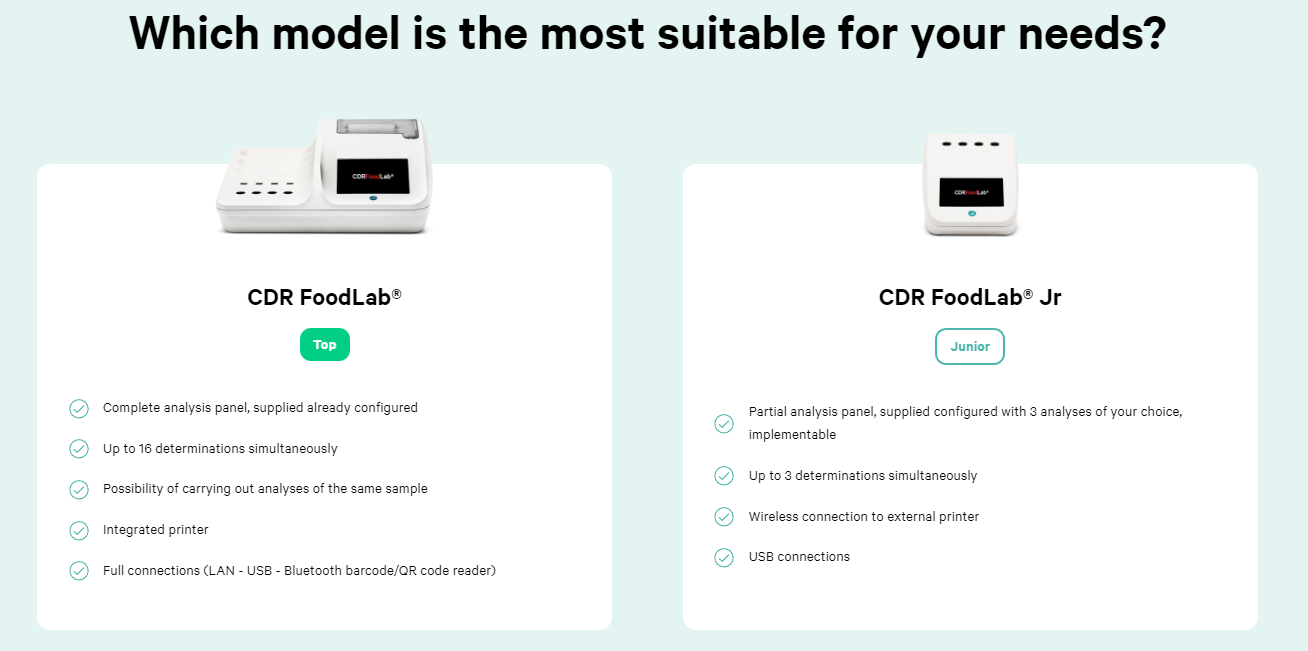

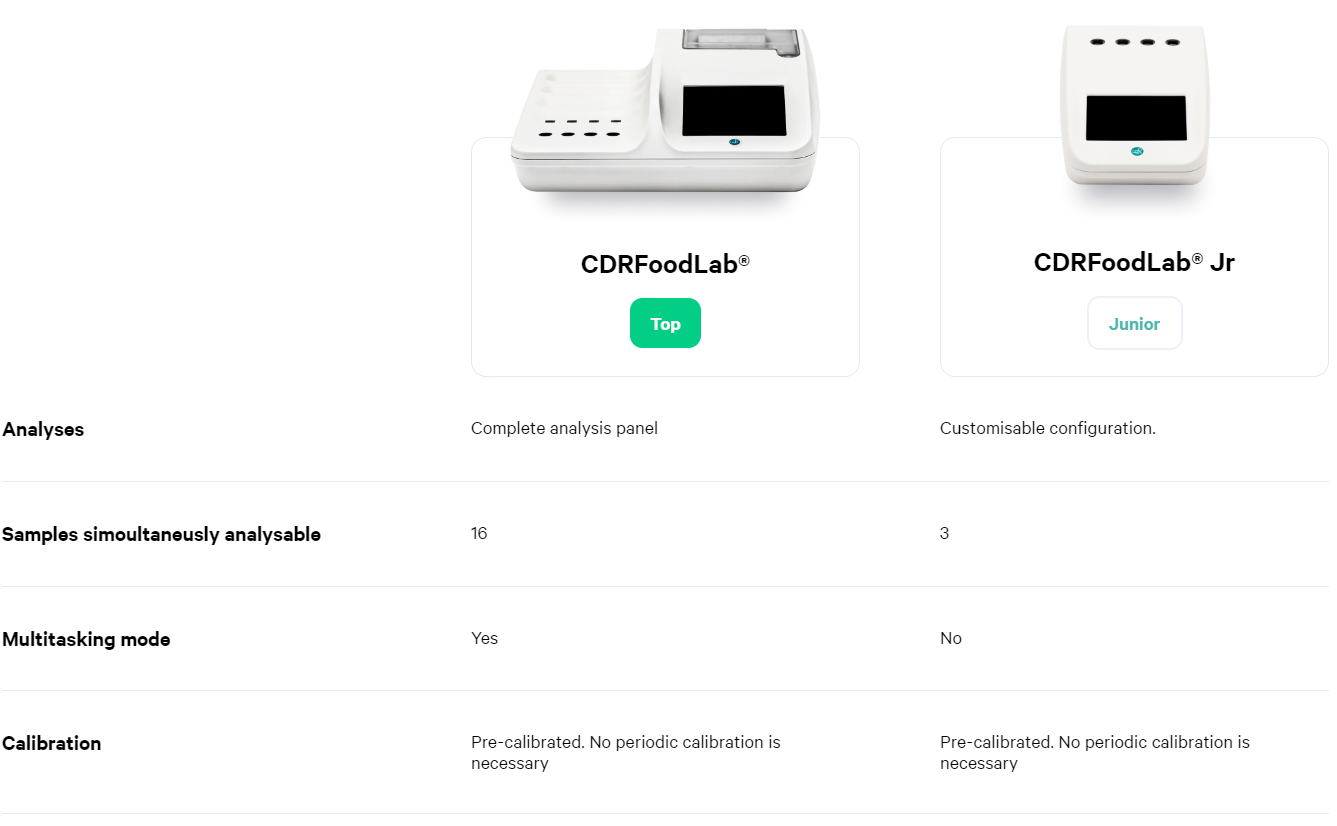

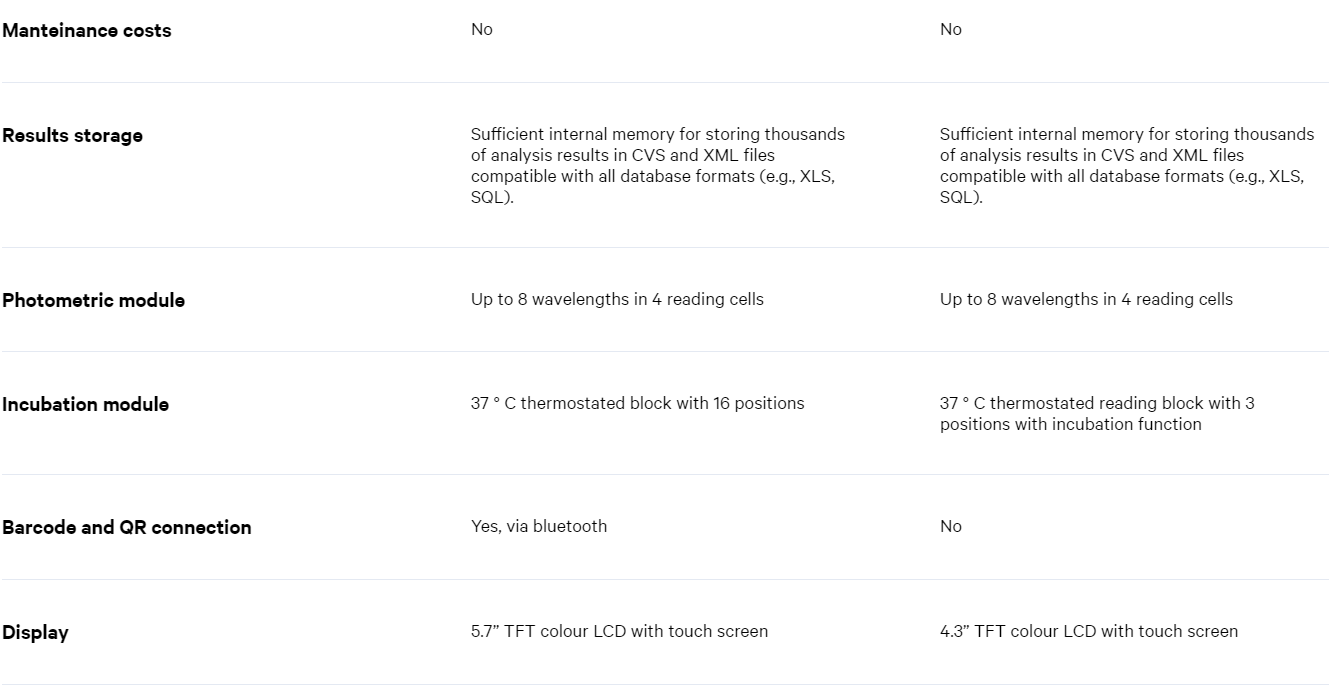

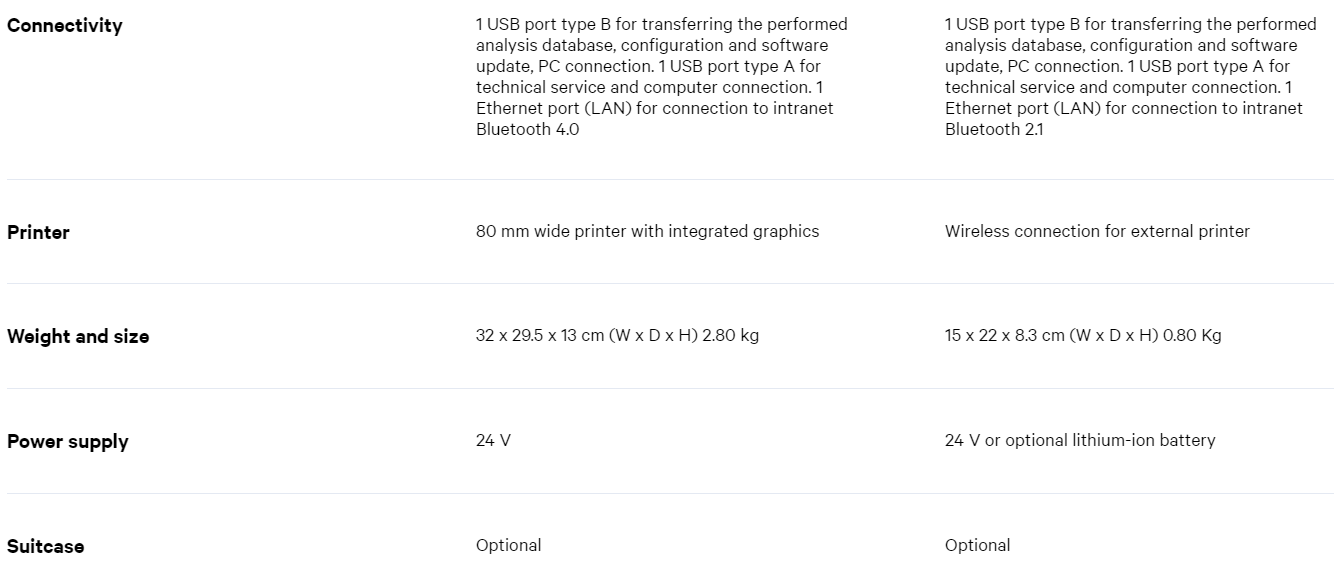

CDR FoodLab® Analyzers for Bakery Product

Quality control of bakery products and spreads

CDR FoodLab® is the analysis system used to perform a complete quality control on bakery products, baked goods, snacks and spreads.

With CDR FoodLab®, quality control on bakery products, baked goods, snacks and spreads can be carried out completely, quickly and easily starting from the raw materials used (oils and fats, milk, eggs) and ending with the finished product. Toxic solvents are not necessary for preparation of the sample and the tests are completed in 10 minutes

Quality controls on the Finished Product

The CDR laboratories have studied very simple and rapid sample preparation systems that do not involve the use of toxic solvents and are used to evaluate the oxidative stability on the finished product, thus obtaining valuable information on rancidity and shelf-life. Furthermore it is possible to determine the presence of the appropriate quantity of lactose in the case of lactose-free products or of alcohol used as a preservative and antibacterial agent.

The analysis on the finished product (bakery products, baked goods, snacks, and spreads…)

- Free Fatty Acids (FFA)

- Peroxide Value

- p-Anisidine Value

- Lactose

- Alcohol by Volume in the antibacterial solution*

- Alcohol by Volume on bakery products

How to determine the shelf life of bakery products, baked goods, and spreads in 4 steps

With CDR FoodLab® is possible to evaluate the rancidity and the value of TOTOX* of the finished products testing Free Fatty Acids, Peroxide Value and Anisidine Value on the extracted fatty material.

Sample processing is extremely simple and free from hazardous solvents:

- in the case of bakery products it is necessary to crush the sample and to add in appropriate proportions the adjuvant for the extraction of water-based fat EXTRAFLUID cod *300133. In the case of spreads it is sufficient to add the adjuvant for extraction;

- in both cases, after brief centrifugation, the fat is obtained as a supernatant.

Acidity, peroxides and p-anisidine with CDR FoodLab ® are determined by a simple photometric method identical to that applied to analysis of the fat used to package the finished product.

In this way it is possible to ascertain the rancidity and value of TOTOX* in real time, thus obtaining important information on the shelf life of bakery products, baked goods, snacks or spreads.

Thanks to the Multitasking Mode, you can concurrently perform Free Fatty Acids, Peroxide Value(PV) and p-Anisidine Value(AV) , so rancidity and TOTOX can be determined in 10 minutes.

*TOTOX= AV + 2PV indicates the general oxidation status of the oil/grease.

Thanks to the use of EXTRAFLUID the risks for the operator are eliminated and the environmental impact is minimised as the quality control of the products of bakery products (bakery products, baked goods, snacks and spreads) does not require longer and complicated extraction processes, toxic solvents, expensive waste disposal or extractor hoods.

Check lactose in lactose-free bakery products

CDR FoodLab ® is used to determine the lactose in bakery products to verify the actual quantity of lactose present in lactose-free products.

The sample preparation is very simple: distilled water in appropriate proportions is added to the ground product to allow its solubilisation.

A clear solution is obtained through a centrifugal action which can thus be easily analysed.

In 10 minutes, with this simple method, reliable and precise results are obtained in accordance with the reference method (HPLC), which requires training, specific knowledge and a great deal of time available.

Check the alcohol content of the finished product

With CDR FoodLab ® the analysis of alcohol content can be performed both on a antibacterial solution and on a finished product, determining the starting alcohol concentration and the final product concentration respectively, in order to avoid exceeding the legal limit.

Also in the latter case the treatment of the sample takes place simply by adding to the crushed product a determined quantity of distilled water which solubilises the alcohol bringing it into solution.

With simple centrifugation a clear solution is obtained which is then easily analysed. The analysis consists of a simple photometric reading.

Analysis

Bakery Products and Spreads

- Free Fatty Acids

- Peroxide Value

- Anisidine Value (AnV)

- Lactose

- Alcohol by Volume

- Alcohol by Volume on Preservative solution

Analytical Kits

| Numero di test | Code | Measuring Range | |

|---|---|---|---|

| Acidity [0.03-1.1] % | kit 100 tests | *300125 | 0.03 – 1.1 % Oleic Acid |

| kit 10 tests | *300128 | ||

| Acidity [0.01-0.59] % | kit 100 tests | *300125 | 0.01 – 0.59 % Oleic Acid |

| kit 10 tests | *300128 | ||

| p-Anisidine | kit 100 tests | *300500 | 0.5 – 100 AnV |

| kit 10 tests | *300503 | ||

| Peroxides [0.3-25] meqO2/Kg | kit 100 tests | *300150 | 0.3 – 25 meqO2/Kg |

| kit 20 tests | *300159 | ||

| Peroxides [0.3-11] meqO2/Kg | kit 100 tests | *300150 | 0.3 – 11 meqO2/Kg |

| kit 20 tests | *300159 | ||

| Peroxides [0.1-5.5] meqO2/Kg | kit 100 tests | *300150 | 0.1 – 5.5 meqO2/Kg |

| kit 20 tests | *300159 | ||

| Lactose [0.01-2 g/100g] | kit 100 tests | *300015 | 0.01 – 2 g/100g |

| kit 10 tests | *300010 | ||

| Alcohol by volume bakery products | kit 10 tests | *300606 | 0.01 – 2.5 %vol |

| kit 100 tests | *300608 | ||

| Alcohol by volume syrup [1-10] % | kit 10 tests | *300613 | 1 – 10 %vol |

| kit 100 tests | *300616 |

How does the analysis take place? Take a look

With CDR FoodLab®, chemical tests on bakery products are performed in just a few steps and results are yielded right away:

- Select the parameter to measure from the menu: the system automatically selects the correct wavelength.

- Use the supplied pipette to add the correct volume of sample to the pre-vialed reagent, specifically developed by our laboratories. A colorimetric reaction is generated.

- Follow the displayed instructions.

The result of the test is automatically calculated, displayed and printed in just a few minutes in its unit of measure.

If you need the Help function will lead you through the analysis process “Step by Step”.

You don’t have to handle toxic or carcinogenic compounds; there is no need to wash either containers or traditional glassware.

You can perform the tests not only in laboratory, but also at production line, even if you don’t have any laboratory technical skills.

Save your time

CDR FoodLab® allows accelerating analytical procedures because you can perform 16 simultaneous tests.

Furthermore, the Multitasking function allows performing several analyses at the same time on the same sample or sixteen different assays for the same parameter on a batch of different samples. All of this in an simple and fast way.

CDR FoodLab® Analyzers for Snacks, Bakery Products, Baked Goods, and Spreads