- Empty cart.

- Continue Shopping

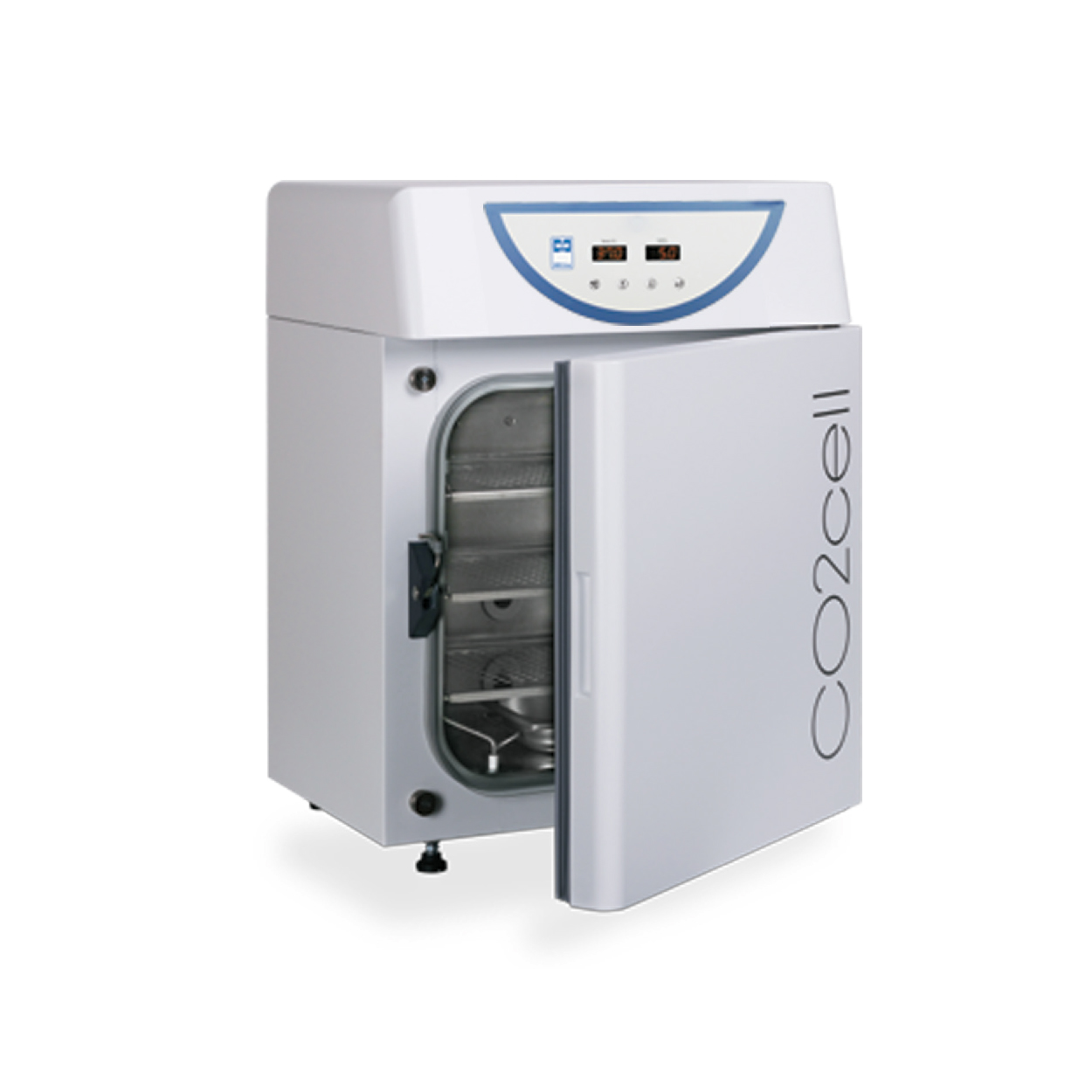

Vacuum Drying Laboratory Ovens VACUCELL 111

RM69,126.00

Variable buttonVacuum Drying Laboratory Ovens VACUCELL 111

RM69,126.00

VACUCELL 111

Ovens with Heat Distribution in Vacuum or Inert Gas

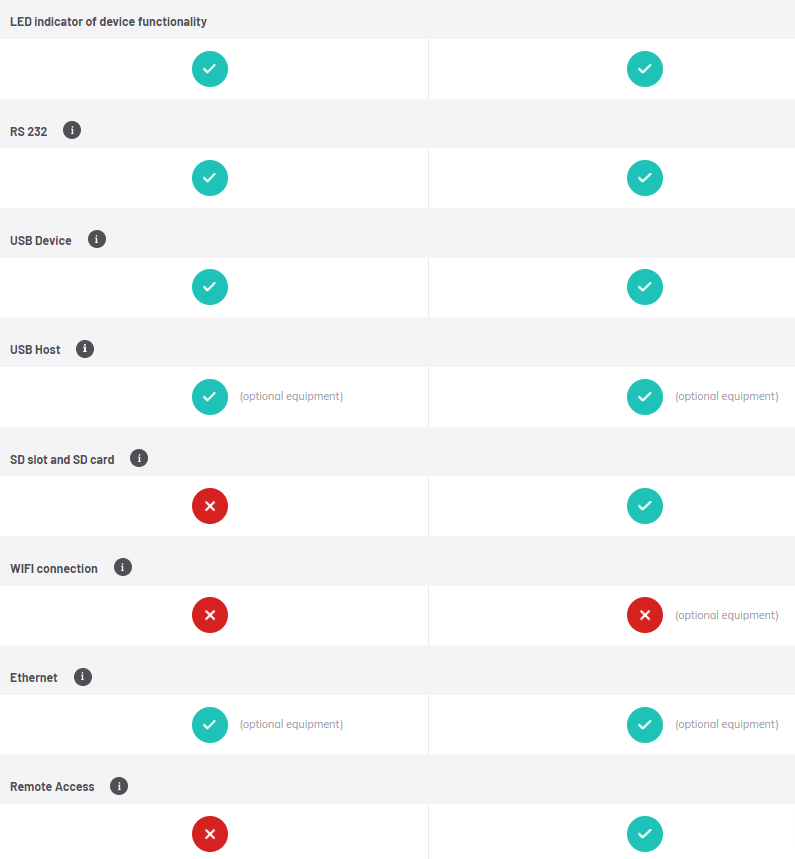

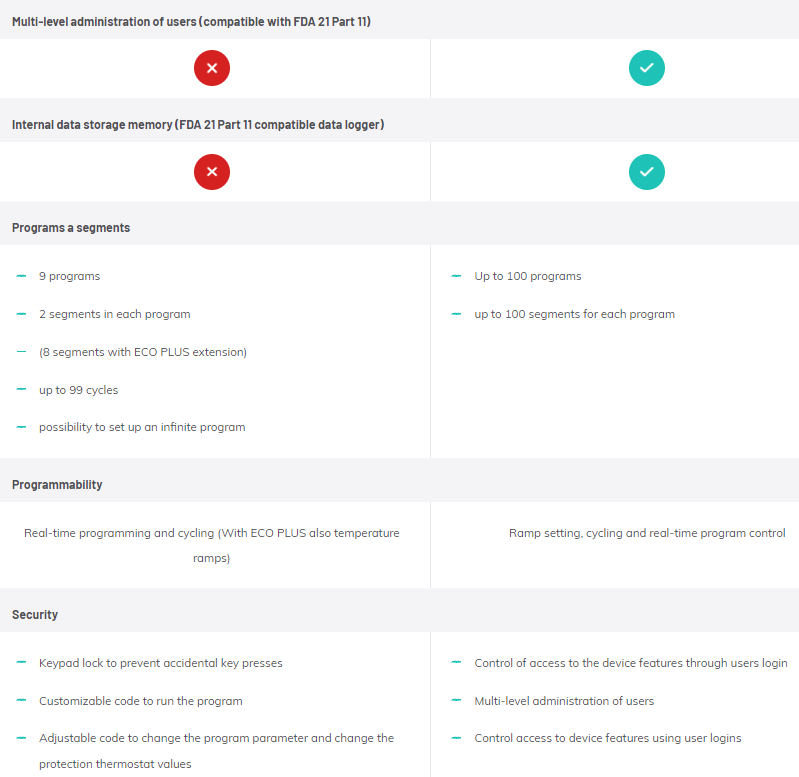

Type ECO Line MC000219

Type EVO Line MC000926

Temperature sensitive, easy decomposable or oxidative materials can be dried very tenderly in VACUCELL® vacuum drying ovens, where there is the opportunity of extrusion of air by inert gas. Also complicated components with hardly accessible hollow spaces are drying quickly and effectively in VACUCELL® ovens. Ideal for drying of samples to constant weight. Special application of the device is possible mainly in the fields of plastics processing, pharmaceutical, chemical, electro technical and other industries.- fast, gentle, environmentally friendly – laboratory drying oven for higher demands

- chamber volume 111 litres

- temperature range from 5°C above ambient to 200°C

- characterized by noiseless operation and gentle sample heating in the chamber, offering high-quality and safe heating and drying of samples up to constant weight

- high operation comfort, precise temperature control and short chamber temperature equalization times after the door opening

- suitable for perfect drying of thermally labile and oxidation sensitive materials, complicated shapes, drying of samples to constant weight, etc. in vacuum

- wide selection of optional equipment and accessories (e.g. supplementing the “Vacustation” base with the option of installing a selected type of a vacuum pump,…)

Specification

Interior of stainless steel material No. 1.4571

volume | 111 l |

depth | 410 mm |

width | 540 mm |

height | 480 mm |

Tray

number | 2 pcs |

racks max. | 8 pcs |

Minimal Shelves distance

height | 43 mm |

Usefull dim. of shelf

width × depths | 480 × 386 mm |

External dimensions (including door and handle)

depth | 650 mm |

width | 760 mm |

heights(incl. foots) | 960 mm |

Package dimensions

depth | 830 mm |

width | 910 mm |

height (incl. palette) | 1100 mm |

Weight

brut | 145 kg |

net | 130 kg |

Working temperature (regulation start)

from 5 °C over ambient temp to | 200 °C |

Temp. deviations acc. to DIN 12 880 Part 2 from working temp – Al shelves pressure 5–10 mbar**

in time to: | 0,4 ± °C |

in space, temperature 100 °C do: | 3 ± °C |

in space, temperature 200 °C do: | 7 ± °C |

Temp. deviations acc. to DIN 12 880 Part 2 from working temp – ss shelves pressure 5–10 mbar**

i time to: | 1 ± °C |

in space, temperature 100 °C do: | 11 ± °C |

in space, temperature 200 °C do: | 26 ± °C |

Time of rise onto 98 % voltage 230 V – (Al shelves pressure 5–10 mbar)

onto temp 100 °C | 110 min |

onto temp 200 °C | 130 min |

Time of rise onto 98 % voltage 230 V – (shelves pressure 5–10 mbar)

onto temp 100 °C | 170 min |

onto temp 200 °C | 220 min |

Heat radiation

at 100 °C | 370 W |

at 200 °C | 750 W |

Vacuum connection

feedthrough needle valve for inert gas or air | 8 mm |

measuring acces (ISO KF) | 40 mm |

vacuum connection measuring DN (ISO KF) Including hose end Ø 12 mm | 16 mm |

Electric parameters – mains 50/60 Hz

nominal voltage | 230 V |

mains 50/60 Hz | 1,8 kW |

current | 7,8 A |

input in stand by mode | 5 W |

Max. permissible load of the shelves

inside the oven | 65 kg/oven |

per shelves | 25 kg |

Available Options

| Thumbnail | SKU | Description | Stock | Price | Quantity | |

|---|---|---|---|---|---|---|

| MC000219 | Vacucell 111 ECO, Vacuum Oven, 111L | RM69,126.00 |