- Empty cart.

- Continue Shopping

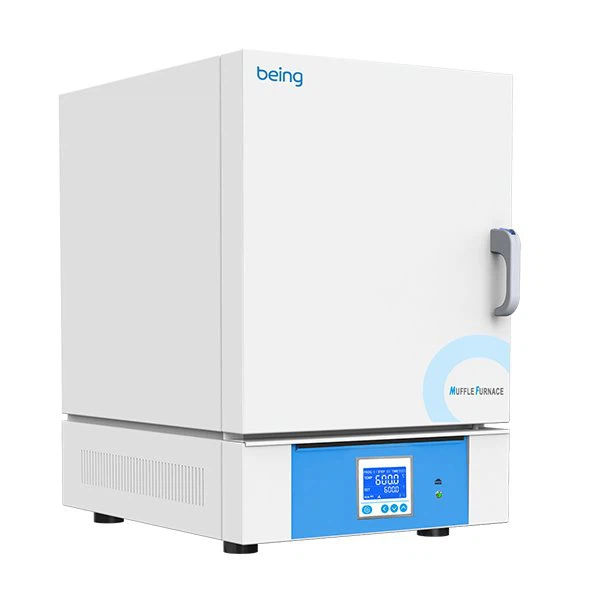

Product Details

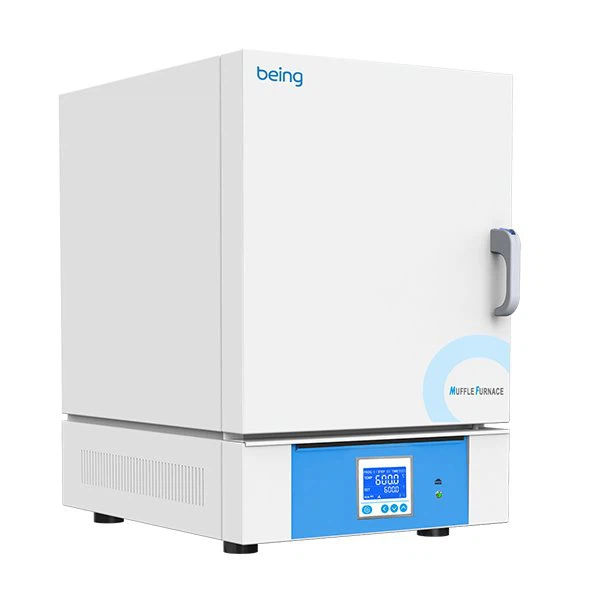

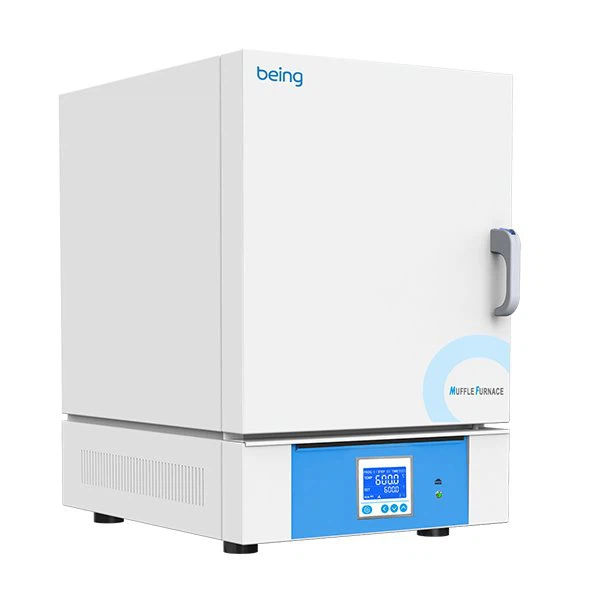

Muffle furnace adopts high quality electric furnace wire and alumina ceramic fiber insulation material provides efficient and reliable high-temperature heat treatment solutions for quenching, annealing, tempering of small steel parts which applied in industrial and mining enterprises, universities and research institutes; Muffle furnace can also be used as pre-treatment for sintering, ashing analysis, etc. of metal, stone tools and ceramics.

Features

The structural design and safety meet international electrical safety standards

Microcomputer PID controller, easy to operate, accurate and reliable temperature control

Programming setting function with 7 periods and 9 steps for each period, which means there are 63 programmable steps in total

High quality heating elements has higher aging resistance, corrosion-resistant ceramic ?ber furnace with light weight, they’re built with long-life.

The chimney ensures the combustion is more complete.

Housing made of sheets of cold-rolled steel finish by powder coated

Present start and off function according customer requirement

Lightweight door design makes opening and closing door safe and easy

Safety

Low noise cooling fan, adjust the external temperature of the furnace body

Over-current, over-voltage, overheat and various safety measures to ensure safety.

The safety switch will automatic shutdown when door open ensures the safety of the operator.

Ceramic fiber furnace insulation material with good heat insulation effect, low temperature on shell surface.

Specifications

| Model | BWF-11/02 | BWF-11/07 | BWF-11/12 | BWF-12/02 | BWF-12/07 | BWF-12/12 | |

| Chamber Volume(L) | 2L | 7L | 12L | 2L | 7L | 12L | |

| Temperature | Maximum(? ) | 1100 | 1200 | ||||

| Working(? ) | 1000 | 1100 | |||||

| Preset start and off | |||||||

| Programmable Controller | |||||||

| Datalogging | USB (option) | ||||||

| Sensor | Type K thermocouple | ||||||

| Insulation material | Alumina ceramic fiber | ||||||

| Heating | Element | Fe-Cr-Al | |||||

| Time(mins) | 35-65 | 30-52 | |||||

| Interior Dimension (WxDxH)mm | 120x 200×80 | 200x300x120 | 300x200x200 | 120x200x80 | 200x300x120 | 300x200x200 | |

| External Dimension (WxDxH)mm | 380x495x584 | 460x650x674 | 490 x690x730 | 380x495x584 | 460x650x674 | 490x690x730 | |

| Safety | Chimney | ||||||

| Over-current protector | |||||||

| Power failure memory | |||||||

| Anti-scalding protection | |||||||

| N/W(Kg) | 35 | 45 | 67 | 35 | 45 | 67 | |

| Power Consumption (Kw) | 1.5 | 3 | 4 | 1.5 | 3 | 4 | |

| Power Supply | 220V 50/60HZ 1P | ||||||

Specifications

| Model | BWF-11/02N | BWF-11/07N | BWF-11/16N | BWF-12/02N | BWF-12/07N | BWF-12/16N | |

| Chamber Volume(L) | 02/07/16 | 02/07/16 | |||||

| Temperature | Maximum(? ) | 1100 | 1200 | ||||

| Working(? ) | 1000 | 1100 | |||||

| Preset start and off | |||||||

| Programmable Controller | |||||||

| Datalogging | USB (option) | ||||||

| Sensor | Type K thermocouple | ||||||

| Insulation material | Alumina ceramic fiber | ||||||

| Heating | Element | Fe-Cr-Al | |||||

| Time(mins) | 35-65 | 30-52 | |||||

| Interior Dimension (WxDxH)mm | 120×200 x80 | 200x300x120 | 300x200x200 | 120x200x80 | 200x300x120 | 250x400x160 | |

| External Dimension (WxDxH)mm | 380x495x584 | 460x650x674 | 490 x690x730 | 380x495x584 | 460x650x674 | 550x800x710 | |

| Safety | Chimney | ||||||

| Over-current protector | |||||||

| Power failure memory | |||||||

| Anti-scalding protection | |||||||

| Power Consumption (Kw) | 2.5 | 4 | 8 | 2.5 | 5 | 10 | |

| Power Supply | 220V 50/60HZ 1P | 380V 50/60HZ 3P | 220V 50/60HZ 1P | 380V 50/60HZ 3P | |||

Available Options

| Thumbnail | SKU | Description | Stock | Price | Quantity | |

|---|---|---|---|---|---|---|

| BE-BWF-11/02 | Muffle Furnace , 1100?C, 2L | RM23,871.00 | |||

| BE-BWF-11/07 | Muffle Furnace , 1100?C, 7L | RM29,314.00 | |||

| BE-BWF-11/12 | Muffle Furnace , 1100?C, 12L | RM38,029.00 | |||

| BE-BWF-12/02 | Muffle Furnace , 1200?C, 2L | RM26,050.00 | |||

| BE-BWF-12/07 | Muffle Furnace , 1200?C, 7L | RM31,500.00 | |||

| BE-BWF-12/12 | RM40,214.00 |