- Empty cart.

- Continue Shopping

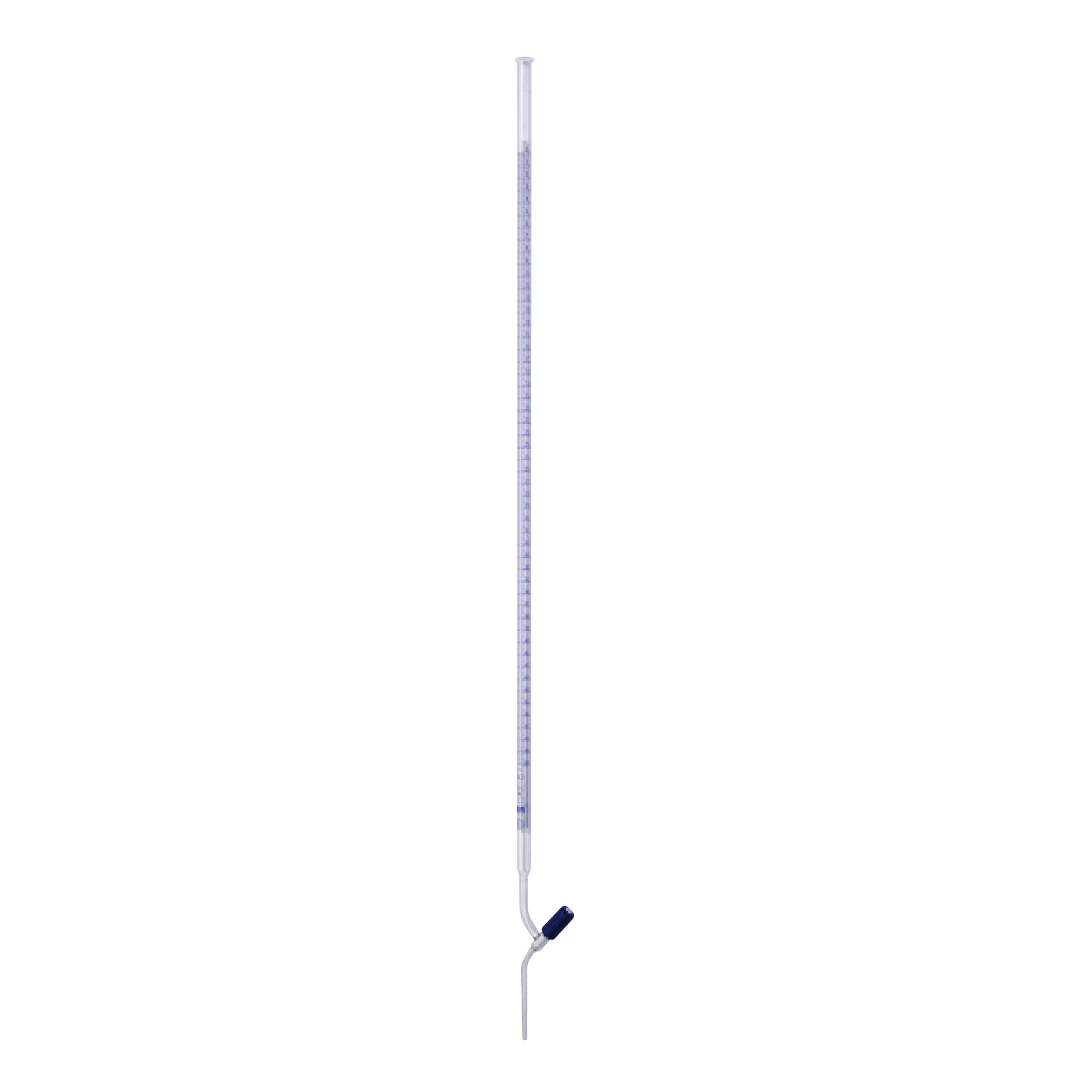

A dispenser with a reagent recirculation system for manual dispensing directly from the reagent bottle. Available in six different volumes.

Uncompromising reliability – years of experience gained by Hirschmann in liquid handling are reflected in the perfection embodied in ceramus® and absolute attention to detail. The graduation gauge and digital volume configuration engagement guarantee consistent precision and volume dispensing and ensure reproducible results – absolutely independent of the user. The dispensing piston made of high-purity aluminium oxide ceramic and the DURAN® glass cylinder guarantee a maximum level of chemical and thermal resistance. The high-quality materials in all parts conveying medium enable use within a temperature range from 4° C to 50° C. The complete unit can be steam sterilised at 121° C without dismantling.

A special HF version designed for dispensing very aggressive media is also available. The piston and cylinder are made of high-purity aluminium oxide ceramic, the valve seats and balls are ceramic and valve springs are made of platinum / iridium.

Overview of details:

- Piston made of high-purity aluminium oxide ceramic

- For fixed and variable volumes, from 0.2 mL to 60 mL

- The complete unit can be steam sterilised at 121° C without dismantling

- Free rotation

- Media recirculating system for simple and rapid venting without reagent loss

- User-independent, reproducible volume dispensing

- Digital volume configuration engagement, calibrated for a lifetime

- Robust ejection unit

- Threaded suction hose fitting

- Optimum chemical and thermal resistance of parts conveying medium

- Individual quality certificate with conformity certificate

ceramus®

| Code-No. | Volume in mL | Graduation in ml | A% | CV% | |

|---|---|---|---|---|---|

| 9312000 | 0,2-1 | 0,05 | 0,6 | 0,2 | |

| 9322000 | 0,4-2 | 0,05 | 0,6 | 0,2 | |

| 9332000 | 1-5 | 0,1 | 0,6 | 0,2 | |

| 9342000 | 2-10 | 0,25 | 0,6 | 0,2 | |

| 9352000 | 5-30 | 0,5 | 0,6 | 0,2 | |

| 9362000 | 10-60 | 1 | 0,6 | 0,2 |

Item List

[variationtable id=”14536″]

Specification

ceramus®

| Code-No. | Volume in mL | Graduation in ml | A% | CV% | |

|---|---|---|---|---|---|

| 9312000 | 0,2-1 | 0,05 | 0,6 | 0,2 | |

| 9322000 | 0,4-2 | 0,05 | 0,6 | 0,2 | |

| 9332000 | 1-5 | 0,1 | 0,6 | 0,2 | |

| 9342000 | 2-10 | 0,25 | 0,6 | 0,2 | |

| 9352000 | 5-30 | 0,5 | 0,6 | 0,2 | |

| 9362000 | 10-60 | 1 | 0,6 | 0,2 |